WHY CHOOSE US?

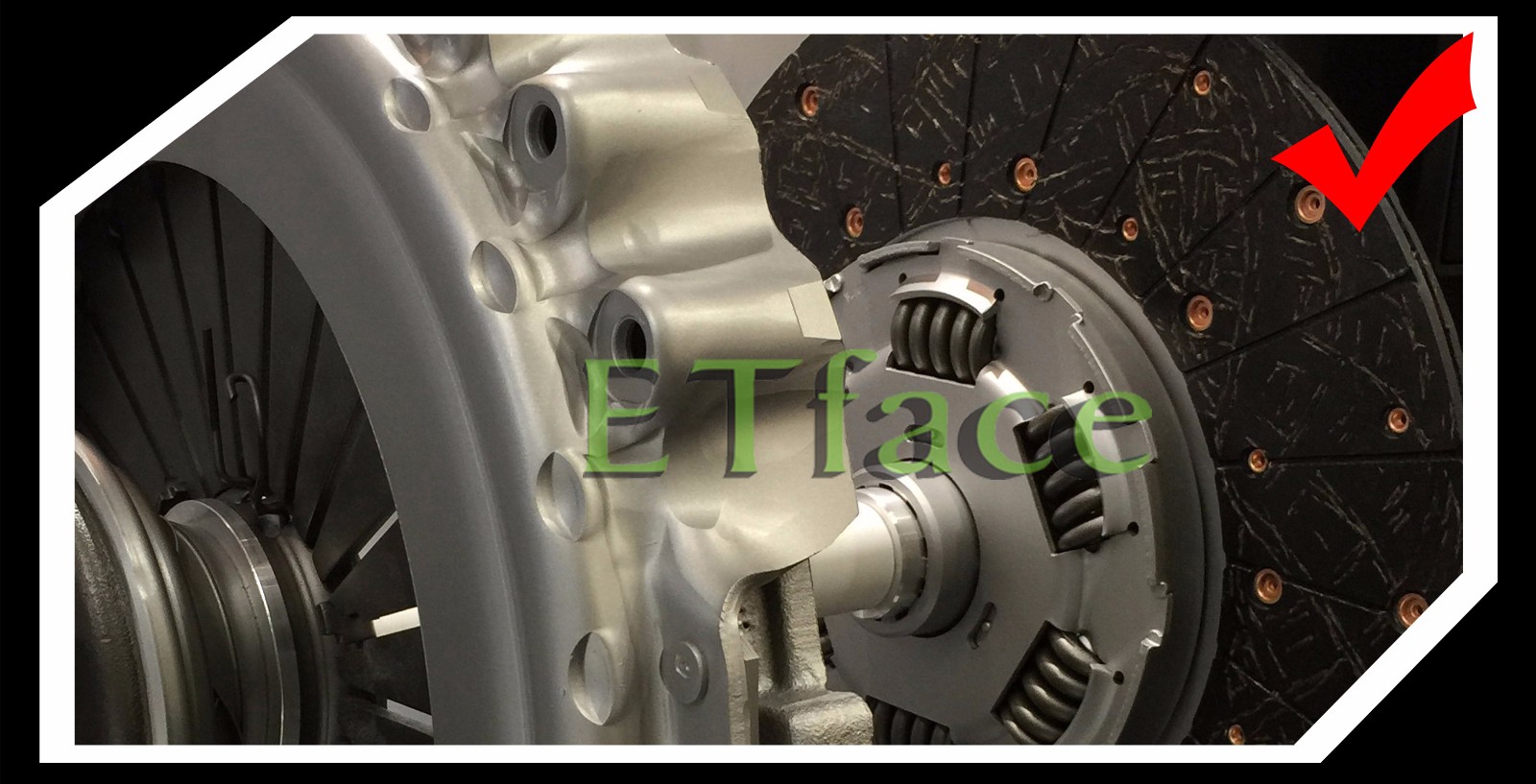

BETTER CLUTCH COVER

ETFACE Factory | Some Other Factory |

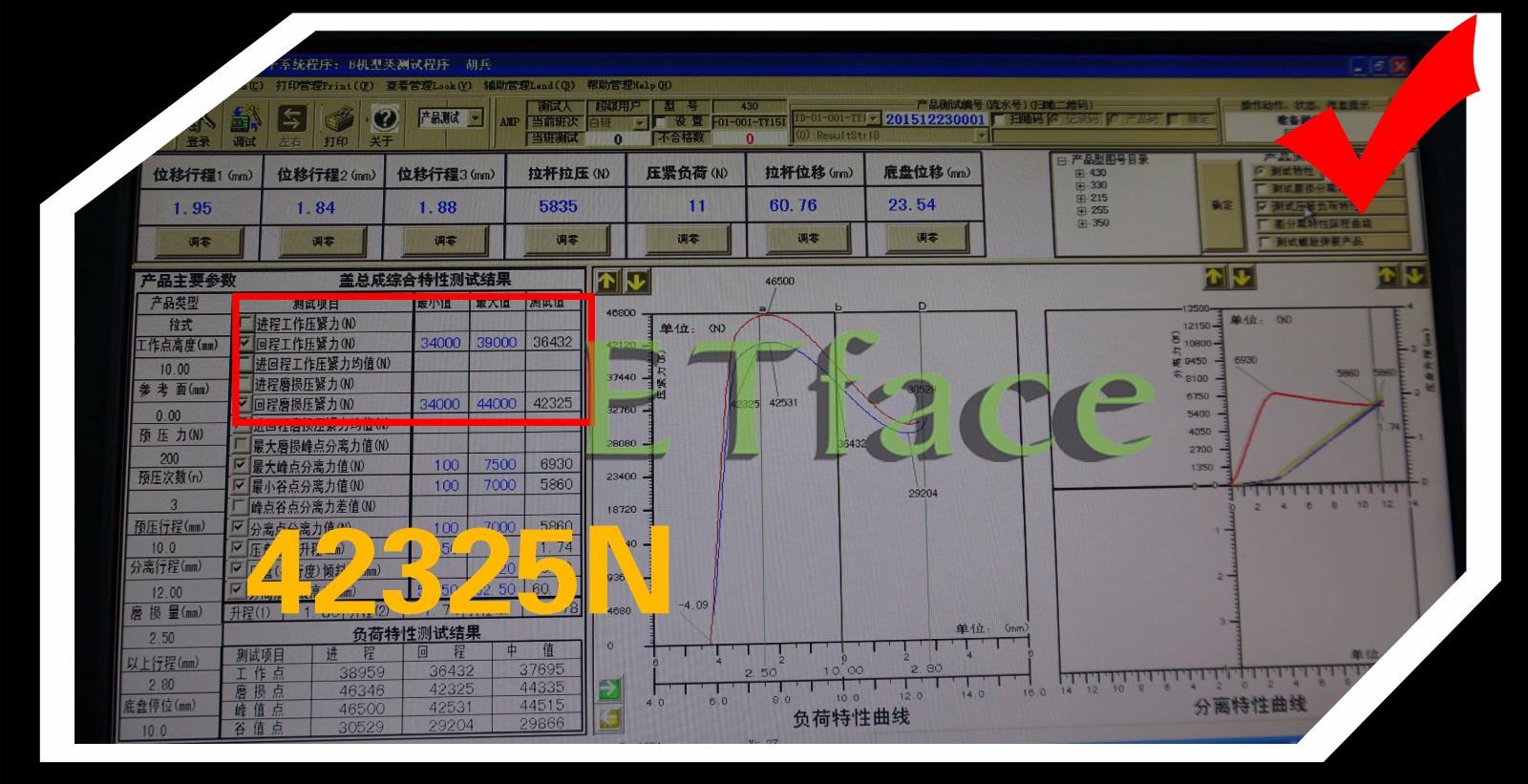

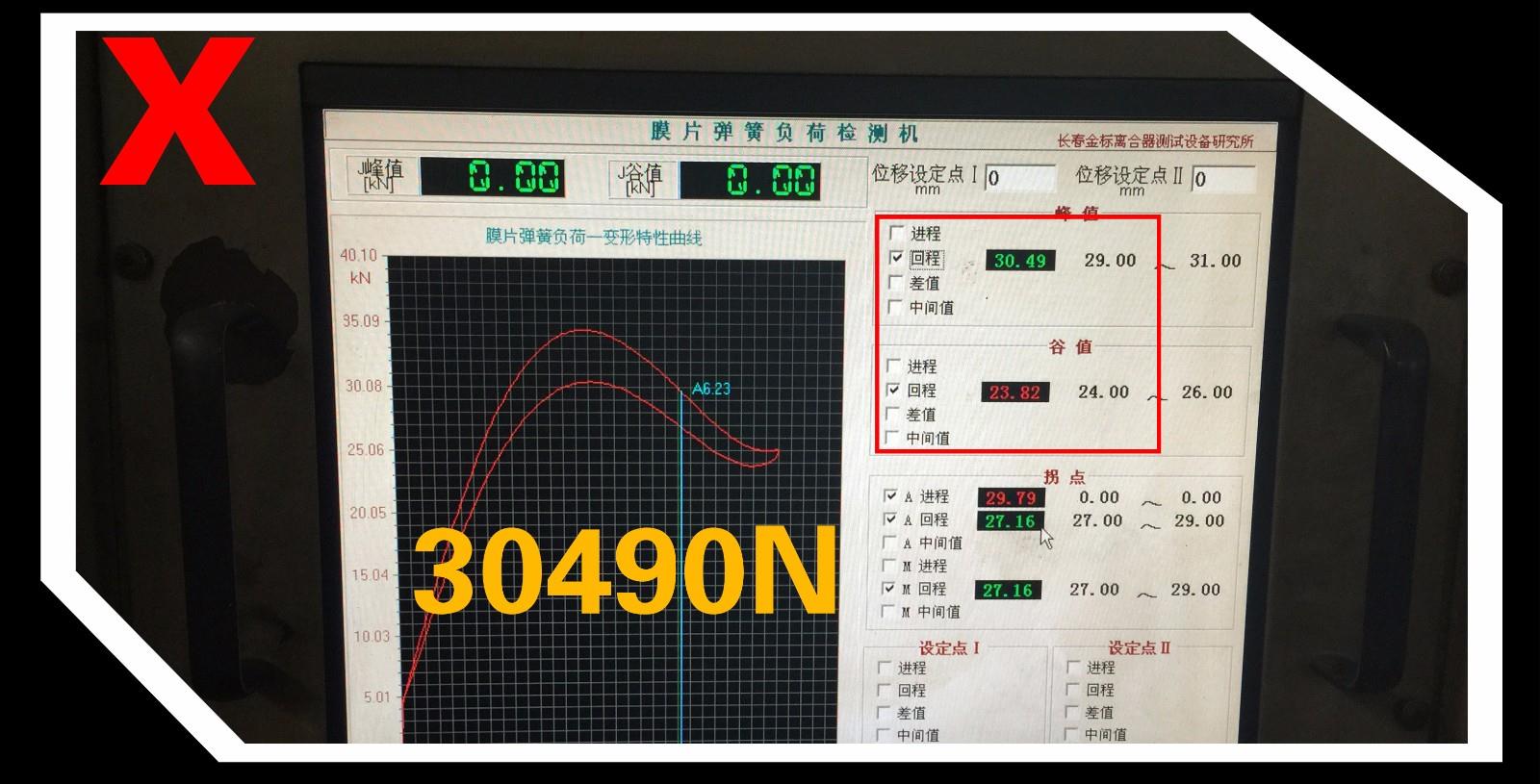

Performance test

The pressure force is 42325N, same as SACHS. The pressure force is 42325N, same as SACHS. |  It is 30490N. It is much lower than SACHS. It has no enough pressure force on the disc, which results in the heating and damage of the facing. It is 30490N. It is much lower than SACHS. It has no enough pressure force on the disc, which results in the heating and damage of the facing. |

Diaphragm

The material is 50CrVA, HRC 55-60 (Tip site), which ensures the high pressure force and guarantee 1.5 million working times, that means at least 6 years working life. The material is 50CrVA, HRC 55-60 (Tip site), which ensures the high pressure force and guarantee 1.5 million working times, that means at least 6 years working life. |  The material is 65Mn, no enough pressure force,after several months using, the pressure force will be declined, which results in slipping between the facing and pressure plate, and heating the facing, getting damaged. The material is 65Mn, no enough pressure force,after several months using, the pressure force will be declined, which results in slipping between the facing and pressure plate, and heating the facing, getting damaged. |

Thickness of the cover

It is 7.3mm,same as SACHS and strong enough. It is 7.3mm,same as SACHS and strong enough. |  It is 5.5mm,not strong. It is 5.5mm,not strong. |

Material of the cover

08AL,same as SACHS, stronger and no damage and no broken inside the material. 08AL,same as SACHS, stronger and no damage and no broken inside the material. |  No good quality material. The material gets broken inside during the molding and pressing.Not strong, easy to get broken when load and change shift. No good quality material. The material gets broken inside during the molding and pressing.Not strong, easy to get broken when load and change shift. |

Pressure plate material

Material:HT250, perfect wear resistance! Material:HT250, perfect wear resistance! |  Material:HT180 or lower quality. Material:HT180 or lower quality. |

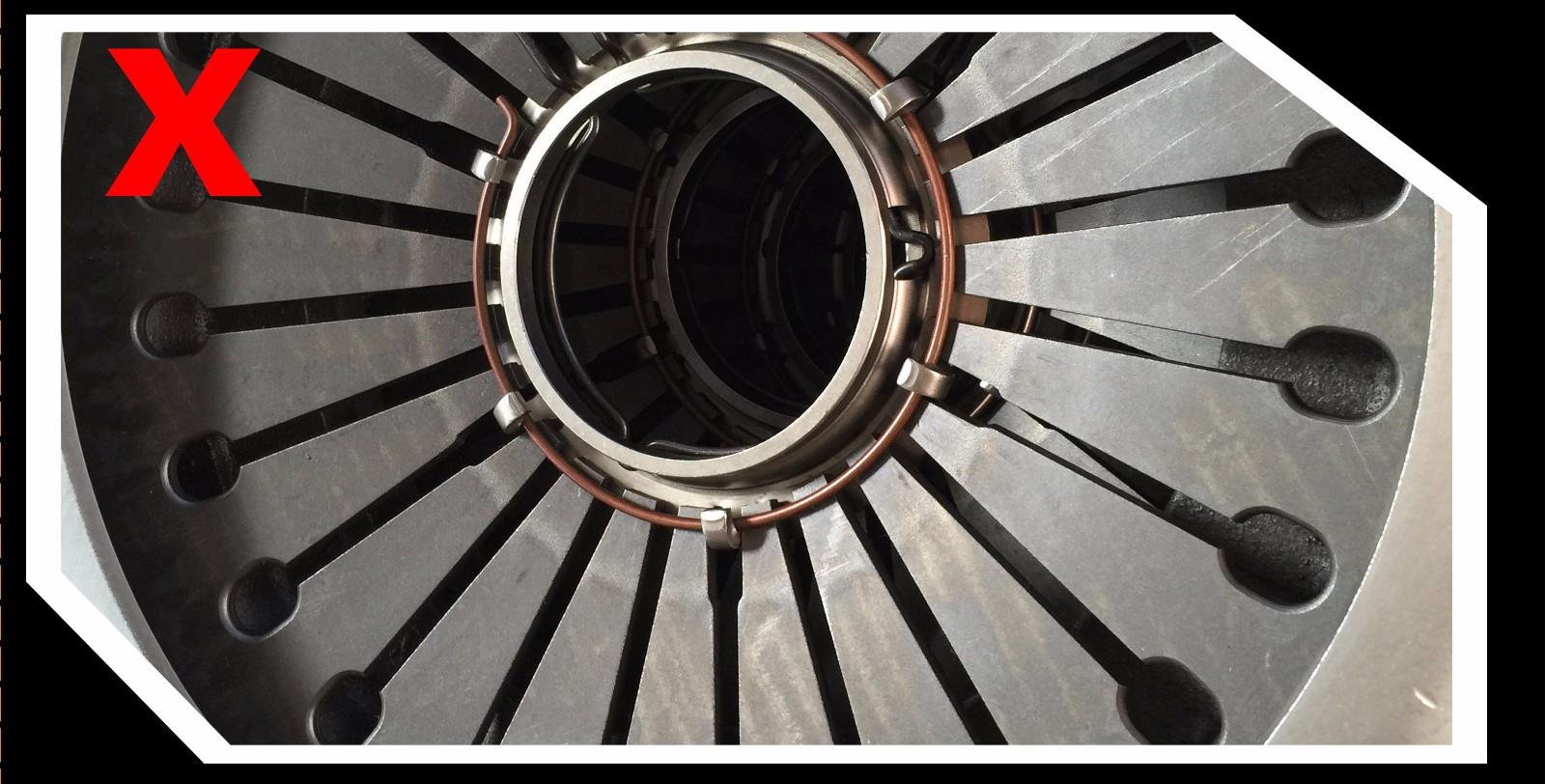

The surface of the pressure plate

Special surface treatment with the fine lines, perfect performance, same as SACHS. Special surface treatment with the fine lines, perfect performance, same as SACHS. |  Not the same as SACHS. Not the same as SACHS. |

Thickness

Thickness:5.08mm, stronger. Thickness:5.08mm, stronger. |  Thickness:1.7mm, not strong. Thickness:1.7mm, not strong. |

Strap

The material:65Mn with high quality heat treatment. Combination of rigidity and elasticity. The material:65Mn with high quality heat treatment. Combination of rigidity and elasticity. |  The material: normal steel, no long life time with the elasticity. When assemble together, there is some space between the straps, cannot fit and work perfectly. The material: normal steel, no long life time with the elasticity. When assemble together, there is some space between the straps, cannot fit and work perfectly. |

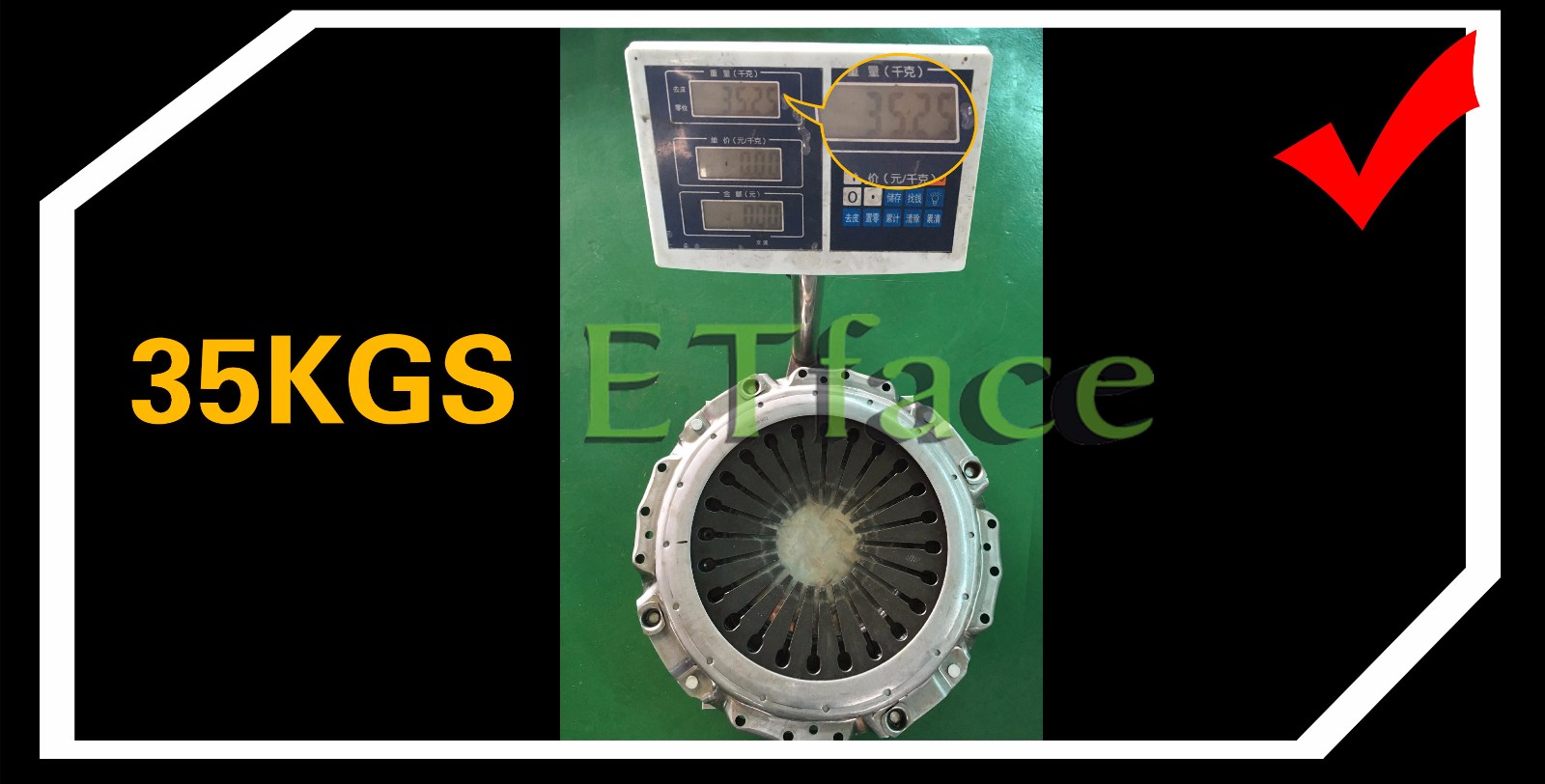

430mm cover assembly weight

For 430mm diameters, normally, it is over 35KGS. For 430mm diameters, normally, it is over 35KGS. |  30KGS, reducing the material. 30KGS, reducing the material. |

Stop collar

Carburized Depth:0.1-0.25mm. Carburized Depth:0.1-0.25mm. |  No carburizing, it is easy to get broken during working. No carburizing, it is easy to get broken during working. |

Packing protection

Same as SACHS, with good protection. Same as SACHS, with good protection. |  No good protection, easy to get damaged during the transportation. No good protection, easy to get damaged during the transportation. |